In sheet metal processing, cracking is more likely to occur when aluminum sheet processing is performed, and many sheet metal processing staff are confused by this. After bending an aluminum plate, why does cracking occur? Then how should be processed to prevent aluminum cracking? Today we will share with you Mingtan aluminum veneer manufacturers: how to avoid cracking phenomenon in aluminum processing:

First of all, let's first understand a few reasons that lead to aluminum bending and cracking:

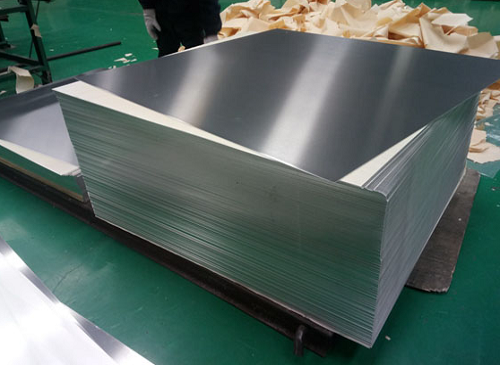

1, the hardness of the aluminum plate

The hardness of the aluminum plate has a direct impact on the aluminum bending cracking, hardness is too high is easy to crack. Then in the aluminum processing, it is necessary to select a number of high-quality aluminum, in accordance with the product's trademark and the condition of the product to check the quality of aluminum, commonly used aluminum 1 series, 3 series, etc., high hardness of 6 series and 7 series, in the processing needs to be done before the annealing process, so that the aluminum plate is O state in order to bend.

2, the thickness of the aluminum plate

Aluminum plate thickness is too thick, it is not easy to bend, so choose a thinner aluminum plate for processing.

3, R angle bending angle

R angle in the bending, the larger the angle, the easier it is to bend, so you should try to bend the R angle is too large.

4, the texture of the aluminum plate

When bending, should be bent according to the texture of the aluminum plate, not parallel bending, choose the straight direction of bending.

5, aluminum pull shape

The appropriate processing procedure should be the first bending, and then pull the shape, which can reduce the probability of cracking.

Considerations for actual processing:

Combined with the actual processing situation, 1060-O state soft, suitable for bending or stamping, 90-degree bending is also possible. But most of the time, aluminum plate both need to bend, but also need to have a certain degree of strength, too soft although the bending is not a problem, but not suitable for most occasions.

At this time, often choose 3003-H24/H112, 5052-O state/H32/H112 and other kinds of, in general, the R angle is a little larger, a little harder aluminum plate can also be bent. Therefore, according to the needs of industrial design, taking into account the processability, aesthetics, strength and durability and other factors, the selection of suitable aluminum alloy, the bending R angle is properly adjusted to arrive at a suitable value.

Online customer service

Online customer service