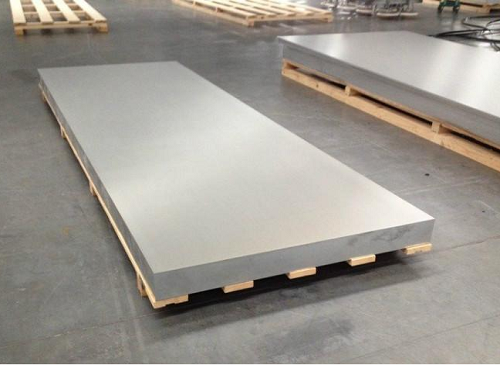

Aluminum panels are also known as pressed aluminum panels, corrugated aluminum panels or aluminum tiles. Corrugated aluminum sheet shape flexible and changeable, beautiful and novel, decorative, can express different architectural styles, is one of the products commonly used in construction, widely used in office buildings, shopping malls, railway stations, airports and other occasions. Henan Mingtan aluminum veneer manufacturers as a professional aluminum manufacturers, with the industry's forward-looking vision, recognizing that corrugated aluminum has replaced the trend of stainless steel and iron plate, so not only to focus on the industry corrugated aluminum manufacturers of product quality control, but also with the actual use of the scene combined with the correct installation of corrugated aluminum panels, to be able to give full play to the advantages of the role of corrugated aluminum panels. Here to share with you some aluminum plate installation considerations:

As we all know, corrugated aluminum panel manufacturers produce a variety of styles, the overall plane effect is good, the lines are clean and beautiful, easy to install, but in the installation process need to focus on controlling the level line. If the release line is not controlled before the installation of corrugated aluminum panels, or if the keel is not leveled, the construction of the device will be affected; if it happens that the keel is not leveled to install the slats first, and the leveling is carried out afterward, the slats will be subjected to uneven force and local deformation will occur. In addition, if the boom is not secure, it will cause localized subsidence, and the slats themselves will be deformed and installed without correction, and an uneven ceiling will occur.

To prevent uneven installation of corrugated aluminum panels, professional corrugated aluminum panel manufacturers remind us of the following issues: the elevation line around the integrated ceiling should be accurately popped up on the wall, and the error should be less than ±5mm, and if the span is large, a control point should be added to the middle of the appropriate location. The pull line control within a section should be straightened, and the slats can be installed only after the keel is straightened and leveled, which is both a reasonable and important process in the construction, especially when the corrugated aluminum sheet is thin, it is easy to be deformed by the uneven external force.

Online customer service

Online customer service