What are the common installation methods and basic performance of honeycomb aluminum veneer curtain wall?

1, lug type: this installation method is to separate the lugs from the honeycomb panel, connect the lugs with the joints of the honeycomb panel and then process the machine separately. The width of the joints should be more than 12mm, this installation method makes the processing simple and easy to install.

2, flap: henan aluminum honeycomb panel this installation process aluminum honeycomb panel with flap processing installation, installation only need to comfort joint and keel joints, applicable to the width of the seam is more than 10 mm, this method is easy to install, but the processing is a little complicated, not suitable for molding curtain wall.

3、Buckle type:This node is aluminum buckle type, buckle type for specific cross-section, easy to install, but this method requires high processing accuracy for the plate, and not recommended to be used in the plate length greater than 3000mm or more. According to the width of the buckle strip, the joints are 20mm and 40mm.

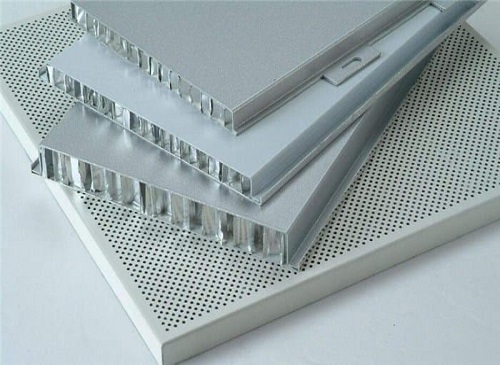

The basic characteristics of honeycomb aluminum veneer.

1, light weight, high specific strength, especially high bending stiffness. The same quality of aluminum honeycomb panel bending stiffness is about 5 times the aluminum alloy plate.

2, Henan aluminum honeycomb panel has high surface flatness and high temperature stability. It is easy to form and not easy to deform. Aluminum honeycomb panel can be made into both flat plate and double curved plate and single curved plate, which is convenient for disassembling and assembling of auto parts.

3, good corrosion resistance, insulation and environmental adaptability, can be adapted to the harsh application environment of railroad rolling stock and passenger cars. In addition, according to the need, this kind of plate can be processed by surface painting or surface paste fireproof board, to achieve good decorative and fireproof performance.

4、Unique resilience, can absorb vibration energy, with good sound insulation and noise reduction effect.

5、Higher fire protection level, in line with UIC564-2-199l "International Intermodal Transportation of Railway Passenger Cars or Similar Vehicles" fire protection and fire prevention specification class a requirements.

6、After fire, the smoke density meets the high standard of international railroad fire prevention. It has good self-extinguishing property, low heat dissipation value, and can form fire-resistant layer, which can reduce the release of smoke and toxic gases, and has excellent environmental performance.

7、Excellent molding craftsmanship, can meet the requirements of complex shapes and high stability requirements for internal parts of railroad vehicles.

Online customer service

Online customer service