Aluminum sheet manufacturer explains the installation process:

1. Skeleton installation

(1) After the completion of the aluminum veneer curtain wall on the facade, the rear anchor of the construction beam at the support, that is, first into the M10 * 110 rear cutting anchor, install the galvanized steel base code. Then weld on the code, after M10 * 110 stainless steel hexagon head bolt will connect the square pipe with the steel code, after the completion of the correction, and then the saw of the horizontal column installed on the main column, the horizontal material installation with fixed welding connection, the other side of the active support, to ensure enough deformation. Finally, all the welded steel members should be removed after the welding slag, coated with anti-rust and zinc-rich paint.

(2) After the skeleton is installed, the shade project will be installed according to the drawing. All screw holes and drawing holes are drilled in the site, and the installed screws must be squeezed on the screw head.

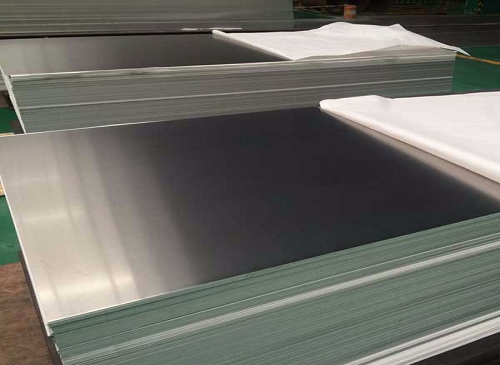

2. Aluminum plate customization

(1) After the skeleton installation, the design technician shall draw the aluminum plate processing drawing according to the practical size of the line, confirm the model, specification, quantity and appearance disposal request, and then the purchaser shall contact the processing matters.

(2) Consumer manufacturers stop cutting, punching, folding, drilling, planting, nailing, welding, filling and reinforcing rib forming according to the aluminum plate processing drawing. Then stop grinding, pre-disposal, drying, spray primer, top coat, cover paint, ju oil, cooling, processing of the final aluminum plate to be inspected after qualified, stop packaging, and then shipped to the site for installation.

3. After the process of aluminum plate, install the control line on the steel keel. Then, the processed aluminum plate is moved to the designated position according to the model, upgraded and adjusted, and connects with the skeleton with the self-drilling self-tapping screw. After the adjustment, lower, left and right, then the next process is entered.

4. Before playing glue and glue, use xylene to clean the appearance of the gel data, and dry with clean white cloth before volatilization, and then fill in the appropriate size of foam tape (the tape should be filled in, no longer deformed), and paste the beauty paper along the glue road, fill the sealant. The glue joint should adhere to plump, and can not be used repeatedly, and then use a special small hanging knife to hang the glue road flat, and finally be careful to tear off the beautiful grain paper, pay attention not to pollute the appearance of aluminum plate.

Online customer service

Online customer service