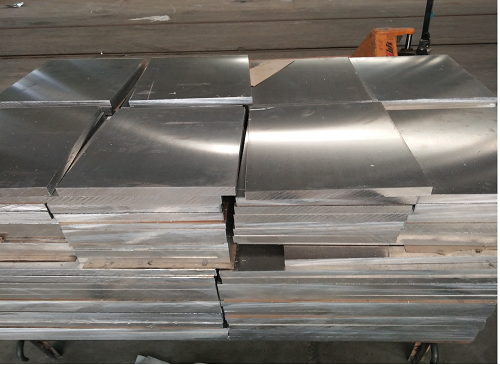

When aluminum veneer manufacturers produce aluminum veneer, the market will encounter such problems, aluminum veneer surface unevenness is one of the frequently encountered problems, so what is the reason for aluminum veneer surface uneven wrinkles? There are many reasons why the aluminum veneer is not qualified, such as aluminum veneer extrusion mold setup problems, support pad problems, etc. Today, I would like to share with you the specific reasons why the aluminum veneer causes surface unevenness:

(1) aluminum veneer extrusion die working belt length and cavity size of the proportion of the wrong design, the speed ratio is seriously out of tune. Curved aluminum square supporting perfect shear, punching, bending and processing of curved panels rolled round machine, can achieve the basic size of 4 meters of various complex shapes of sheet metal processing (many manufacturers can achieve more than 6 meters of processing, but the longer the length, the worse the flatness). Stone aluminum veneer has a certain residual value, but because of its expensive cost, compared to almost no residual value of aluminum composite panels, resulting in waste is still much larger. Capsule hotels are bigger not aluminum composite panels are processed at the site into the required shape and specifications, with greater freedom of construction. And aluminum veneer is processed in the factory forming, due to the relationship between the accuracy of domestic equipment, often in the construction process will encounter some small trouble.

(2) Aluminum veneer extrusion die has obstruction angle and flow promotion angle.

(3)Aluminum veneer extrusion upper and lower die work belt drop ratio is super poor.

(4)The upper and lower die bands of aluminum veneer extrusion die are not parallel and have angular opening.

(5) aluminum alloy veneer extrusion die cavity on the die resistance (sub) level of high blocking work belt discharge or drainage groove (size, depth, location) is not right.

(6) aluminum veneer extrusion die work belt outside the empty knife too little or even no (EDM laying is not good) or too large (work belt cracking deformation without support).

(7) new mold or repaired aluminum veneer extrusion China mold enterprises due to the mold factory rough sand polishing work belt uneven problems arising from the mold design work belt smoothness varying in size.

(8) Part of the aluminum veneer extrusion work belt oil stains.

(9) The support pad is too small to block.

(10) Aluminum veneer end about 1m at the wave (V3 coil aluminum pressed in).

Online customer service

Online customer service