Regardless of which industry, a production company needs to start from the quality of the product, quality is the basis for enterprise development, if the quality of the product is not guaranteed, then there will be some safety risks, then in the aluminum veneer industry, the quality of the product is not only the effect of the decorative effect, but also affects the practicality of the product, today we Mingtan aluminum veneer manufacturers will discuss what factors affect the quality of aluminum veneer products? I will take you a simple understanding of the advantages and disadvantages of aluminum veneer:

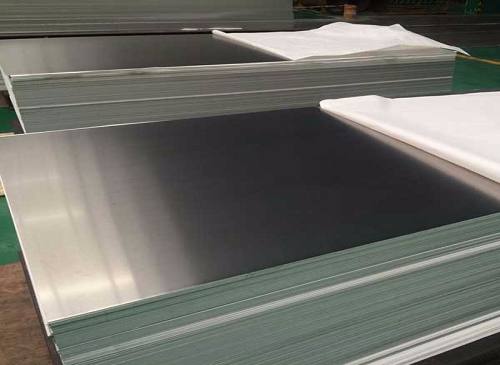

1, look at the smoothness of the product appearance

In order to understand the aluminum veneer surface is smooth, whether combined in the bend, usually as a high-quality aluminum veneer products, from raw materials to processing and production should be strictly inspected, plate processing equipment and workers' technical level will affect the aluminum veneer surface changes in flatness, usually aluminum veneer in the CNC machine tool bending height of about 2 cm, bending to maintain the appearance of the quality of 90 degrees, can be based on these criteria to determine the aluminum Veneer appearance quality.

2, aluminum veneer surface coating observation

High-quality aluminum veneer generally use high standard imported coatings, can ensure that the spraying process of the paint surface is smoother and more wear-resistant, not only need good paint, but also need advanced spraying equipment is generally an automatic electrostatic spraying production line, in the spraying process can be better to ensure that the paint surface of the uniform density of the same, generally need to be in the dust-free workshop is not mixed with dust. Therefore, the spraying process can ensure that the surface of the aluminum veneer with high precision, the handle is also very smooth, so that the surface of the aluminum veneer without chromatic aberration, to achieve the aluminum veneer spraying standards.

3, aluminum veneer thickness observation

Observation of aluminum veneer thickness standard, the aluminum plate in quality in line with national standards, in some of the fake and shoddy aluminum veneer products, the wall thickness error is larger, the middle is relatively thin, the product joint gap is also larger.

4, aluminum veneer compression performance test

Pressure can be pressed down by the middle part of the aluminum veneer, to see whether there is deformation, generally high quality aluminum veneer products have high strength, poor compression resistance, can meet the national standard range of decorative building materials, and aluminum veneer products have poor compression ability, its compression ability is poor, there will be deformation, so as to ensure that the effect of decoration and quality.

The combination of the above methods can distinguish the advantages and disadvantages of aluminum veneer, and generally can judge the quality of the product. I hope this content can help you buy aluminum veneer.

Online customer service

Online customer service