Hear the name of the patterned aluminum, I believe we can literally understand that it is a patterned aluminum metal plate, but often the same thing will not be as simple as we hear and see. So, patterned aluminum panels ultimately have what is not simple characteristics, what are their respective uses, and how to device protection?

First of all, patterned aluminum plate is very uncomplicated. Want to make a rule of thumb pattern on the aluminum plate is not very simple, which means that the processing of one more process, not only add the investment in machinery and equipment, more costly manpower and energy, the cost is greatly increased; the appearance of the pattern does not just play a decorative and beautifying effect, and more is to assume a special use of the environment of the anti-skid effect, like the more clear the texture, the more anti-skid and grip ability of the tires. The clearer the texture, the stronger the tire's anti-skid and grip ability.

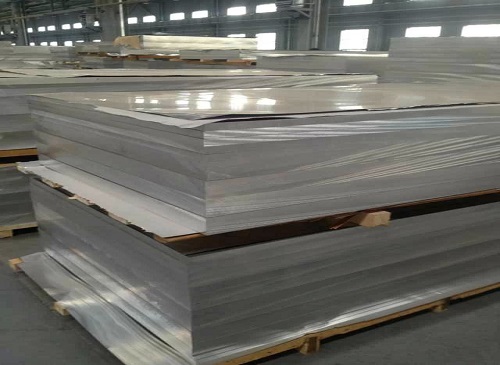

Secondly, there are many types of patterned aluminum sheet can be used in different occupations. Usual aluminum alloy plate, that is, the usual 1060 aluminum plate as the material for processing and become, production and processing cost is relatively low, applicable to the usual conditions of the cold storage, vehicle floor;

Second, aluminum-manganese alloy sheet, is to aluminum-manganese alloy 3003 as the main material for processing and become, has a certain strength and impact resistance, there must be a certain rust and corrosion resistance, the primary application in the train carriages side;

Third, aluminum-magnesium alloy plate, is processed with 5052 or higher levels of aluminum, with high strength and hardness, rust and corrosion resistance is very strong, can be used for ships and even aerospace industry side.

Finally, patterned aluminum is also a metal material, in the daily use of the process also need to use scientific methods for protection:

First, regular cleaning, on the appearance of the stains to use water or the corresponding stain remover for cleaning, the residual stains are simple to form the corrosion and deformation of the plate;

Second, the use of professional spraying agent on the plate appearance of the film treatment, on the one hand, can give the patterned aluminum plate constitutes more than one barrier to avoid corrosion, on the other hand is able to play the effect of landscaping and decoration, to help it very well into the use of the environment in the evening.

With the growing demand for aluminum panels in all walks of life, the panels themselves are constantly undergoing a transformation of skills, patterned aluminum is just the product of this transformation, which presents the traditional aluminum and other panels gradually faded out of the mall, because it has a number of excellent features. However, anything in the application process will attack the corrosion and wear and tear, still need to strengthen the protection and maintenance operations, to extend the service life.

Online customer service

Online customer service